Products

- Home

- Products

- Hot Melt Adhesives

- Low melting

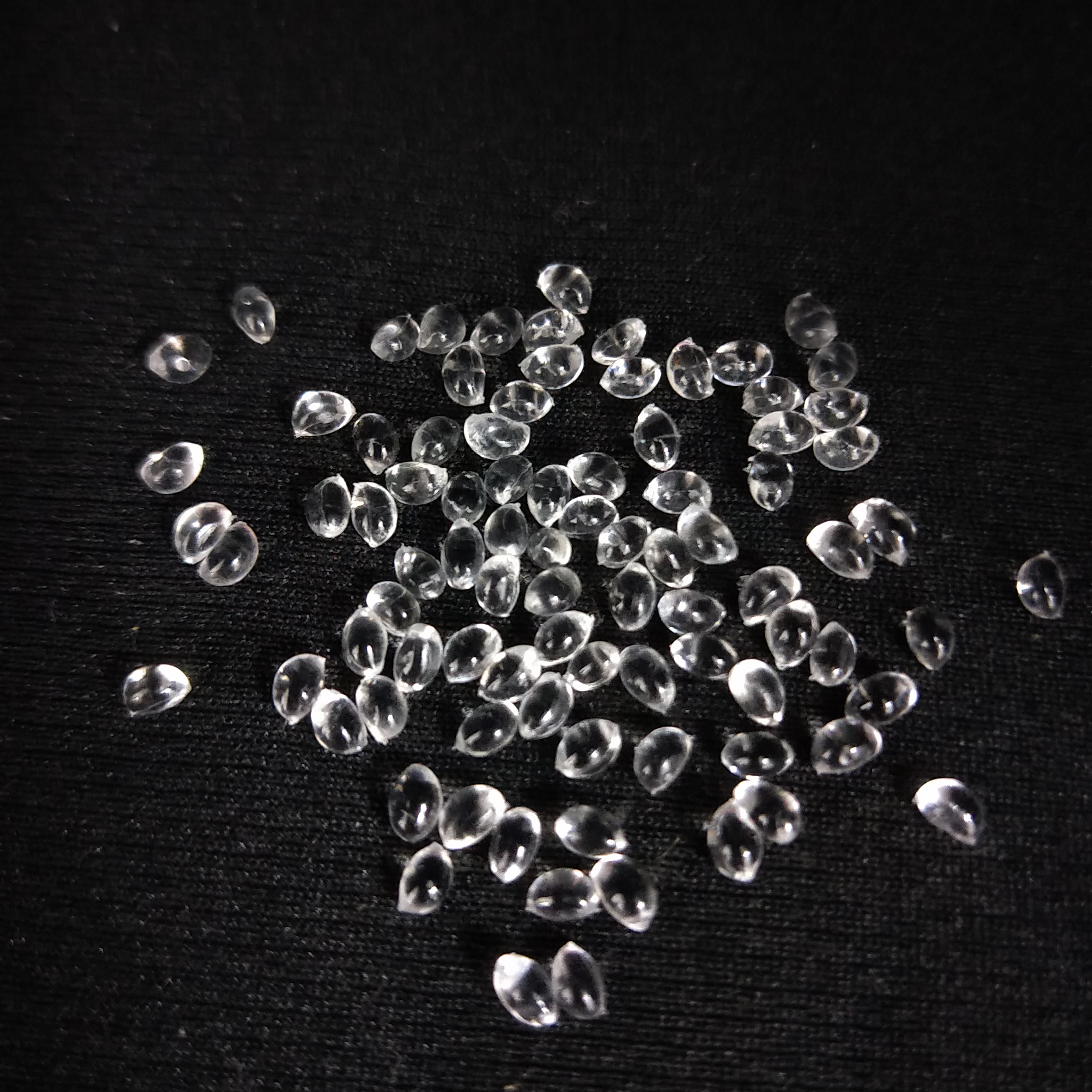

- Low melting

Low melting

Low melting

Details- Features

- Environment friendly

- Easy processing

- Excellent flexibility and toughness

- Low-temperature plasticity

- High initial bonding strength

Description

Hot melt adhesives (HMA) is made of thermoplastic polyurethane, it can be coated or laminated on substrate, after being cooled to solidify the bonding strength will increase immediately. As a green materials, there is no solvent in hot melt lamination process, TPU HMA provides safe and clean working environment, and can be recycled.Besides the excellent adhesion, our product possess high tensile strength, tear strength, low temperature impact, low tensile set, high elasticity recovery and also with wide range of processing temperature and hardness. Our products can be applied on hot melt adhesive film, shoe material application, textile lamination, non-sewing processing, seam sealing tape, water pipe, automobile industry, furniture industry and consumable electronics items… etc.

Specifications

| Items | MZ060 | MZ068 | MC161 | MG370 | MB370 |

|---|---|---|---|---|---|

| Testing Temperature (℃) | 150 | 150 | 177 | 150 | 150 |

| MI (g/10mins) | 10~15 | 10~15 | 15~20 | 6~10 | 5~10 |

| Ts (℃) | - | 70~80 | 50~65 | 60~70 | 63~73 |

| Tfb (℃) | 70~85 | 80~90 | 70~85 | 85~95 | 80~90 |

| Hardness (Shore A) | 65A | 65A | 65A | 70A | 75A |